Batch Centrifuges

CL1800 installation

C52 battery

Unique in their robust simplicity, Broadbent batch centrifuges are ideally suited to the sugar processing industry and are used worldwide in refineries, cane or beet factories for heavy duty, high capacity performance.

Key features

- basket designed for maximum safety

- fully compliant with the highest current standards

- IP55 standard motor (CLX) or Broadbent motor (CL)

- unique clean screen discharge system

- custom-designed motors for high cycle rates

- simple mechanical design

Key benefits

- long basket life with corrosion resistant construction

- excellent crystal recovery from sugar discharge system

- low water usage giving reduced evaporative energy demand

- energy-efficient drive systems

- high throughputs from custom designed motors

The Broadbent range of batch centrifuges

Our standard range includes batch centrifuges to suit a wide variety of sugar and sweetener applications. However, should you require bespoke designs, our Industrial Process Division is at your service to create batch centrifuges to your exact specifications.

| Model | Max basket capacity (kg) | Max separating force G | Max cycles per hr | Max capacity (t/h) |

|---|---|---|---|---|

| C26M | 850 | 1,500 | 25 | 21 |

| C28M | 1,000 | 1,000 | 25 | 25 |

| C32M | 1,300 | 1,050 | 25 | 32 |

| C46M | 1,500 | 1,050 | 25 | 37 |

| C52M | 1,750 | 1,050 | 25 | 43 |

| C58M | 2,100 | 1,050 | 25 | 52 |

| C60M | 2,300 | 1,050 | 25 | 57 |

| Model | Max basket capacity (kg) | Max separating force G | Max cycles per hr | Max capacity (t/h) |

|---|---|---|---|---|

| CL/X1400 | 1,400 | 1,100 | 28 | 39 |

| CL/X1800 | 1,800 | 1,100 | 28 | 50 |

| CL/X2300 | 2,300 | 1,000 | 28 | 64 |

The above quoted capacities and charges per hour are indicative only.

For further details on batch centrifuges, please see our Brochures and

Technical information, or click here to contact the Broadbent Sugar & Sweetener Division directly.

Excellent sugar crystal removal from the basket.

CL1800 centrifuge operating in refinery

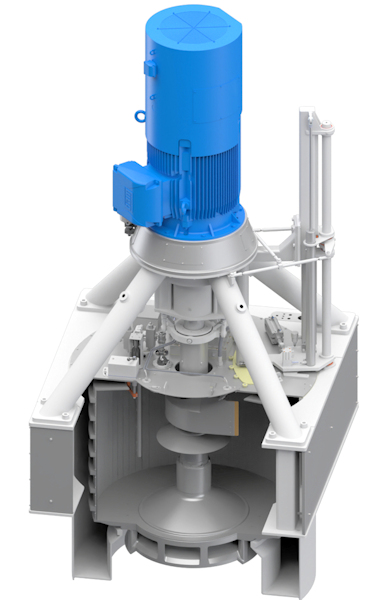

Broadbent CLX1800 (TEFC motor)

Optional extras include:

- stainless steel contact parts

- stainless steel support frame

- high-power drive options

- Broadbent motor or standard TEFC motor option

- separation of washings and molasses (molasses classification)

- maintenance contracts

- remote maintenance/diagnostic access to control plc via web

- mixer tanks

- sugar conveyors.

A unique design of batch sugar centrifuge

The key commercial benefits of the Broadbent clean screen sugar discharge ploughing system include:

- higher crystal yields

- higher throughputs

- lower steam consumption (recirculation to the pans is reduced)

- huge reduction in screen wash water requirements

- lower evaporative steam demand.

For further details on the Broadbent clean screen ploughing system, please see our Brochures and Technical information, or click here to contact the Broadbent Sugar & Sweetener Division directly.